AS9100 Aerospace

Popular

Description

Course Title:

AS9100 Aerospace Quality Management Systems Training

Course Objective:

To provide participants with a comprehensive understanding of the AS9100 standard, its requirements, and its application in aerospace quality management systems. The course equips learners with the skills to implement, maintain, and audit AS9100 in their organizations to meet industry compliance and enhance quality performance.

Learning Outcomes:

By the end of this course, participants will be able to:

- Understand the structure and requirements of the AS9100 standard.

- Identify the unique quality requirements of the aerospace industry.

- Develop and implement an AS9100-compliant Quality Management System (QMS).

- Conduct internal audits to ensure compliance with AS9100.

- Integrate risk management and continuous improvement processes into the QMS.

- Analyze gaps between current organizational practices and AS9100 requirements and formulate actionable plans to close them.

- Communicate effectively with stakeholders regarding AS9100 implementation and audit outcomes.

Course Outline:

Module 1: Introduction to AS9100

- Overview of Quality Management Systems (QMS) in Aerospace

- History and evolution of AS9100

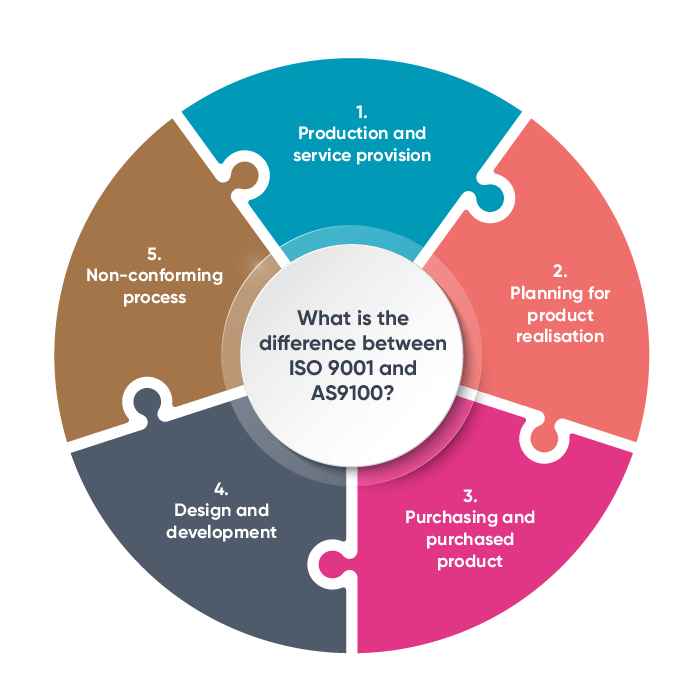

- Key differences between ISO 9001 and AS9100

- Benefits of implementing AS9100

Module 2: AS9100 Standard Structure and Requirements

- Introduction to Annex SL (High-Level Structure)

- Detailed review of AS9100 clauses:

- Context of the organization

- Leadership and commitment

- Risk-based thinking and planning

- Support and resource management

- Operation: Product and service realization

- Performance evaluation and continuous improvement

Module 3: Implementing AS9100 in an Organization

- Steps for establishing an AS9100-compliant QMS

- Documentation requirements

- Process mapping and management

- Integrating AS9100 into existing business processes

Module 4: Risk Management in Aerospace

- Risk-based thinking in AS9100

- Identifying, evaluating, and mitigating risks

- FMEA (Failure Modes and Effects Analysis) and other tools

Module 5: Auditing and Certification Process

- Types of audits (internal, external, and third-party certification)

- Preparing for an AS9100 audit

- Conducting internal audits and creating audit reports

- Common non-conformities and how to address them

Module 6: Continuous Improvement and Best Practices

- Root cause analysis for corrective actions

- Tools for continuous improvement (Lean, Six Sigma, etc.)

- Best practices for sustaining AS9100 compliance

Module 7: Practical Exercises and Case Studies

- Workshop: Writing QMS documentation

- Case study: Gap analysis for AS9100 compliance

- Mock audit simulation

Module 8: Course Wrap-Up

- Key takeaways

- Final Q&A session

- Assessment and certification

Methodology:

The course will adopt a mix of instructional methods to engage participants and enhance learning outcomes:

- Interactive Lectures: Clear, concise presentations of AS9100 concepts and requirements.

- Case Studies: Real-world examples from the aerospace industry to contextualize learning.

- Workshops: Hands-on activities, including documentation writing and risk analysis.

- Group Discussions: Peer learning through the exchange of experiences and insights.

- Mock Audits: Simulated exercises to practice auditing skills.

- Assessments: Quizzes and final evaluations to gauge understanding and readiness.

- Q&A Sessions: Opportunities for participants to clarify doubts and deepen understanding.

Location

Review

Write a ReviewThere are no reviews yet.