Popular

Machinery Safety

Description

Course Outline

Module 1: Introduction to Machinery Safety

- Importance of machinery safety in the workplace

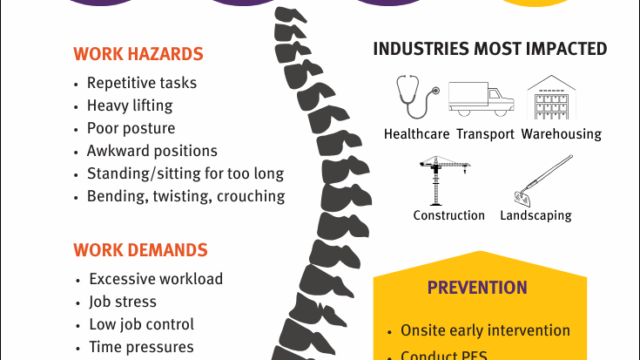

- Common hazards associated with machinery

- Overview of machinery-related accidents and their consequences

Module 2: Understanding Machinery and Risk Assessment

- Types of machinery and their applications

- Identifying mechanical hazards (e.g., crushing, cutting, entanglement)

- Principles of risk assessment and hazard identification

- Safety standards and legal requirements (e.g., OSHA, ISO 13849)

Module 3: Machine Guarding and Safety Controls

- Types of machine guards (fixed, adjustable, self-adjusting)

- Importance of safety devices (e.g., interlocks, emergency stop controls)

- Ergonomic considerations in machine design

Module 4: Safe Work Practices and Procedures

- Pre-operational checks and inspections

- Proper use of Personal Protective Equipment (PPE)

- Lockout/Tagout (LOTO) procedures for machinery maintenance

- Training and supervision of machine operators

Module 5: Emergency Response and Accident Management

- Emergency protocols for machinery-related incidents

- Reporting, investigating, and documenting accidents

- Steps for corrective and preventive actions

Module 6: Practical Training and Case Studies

- Hands-on exercises with machinery safety systems

- Real-world case studies and lessons learned

- Group discussions and Q&A sessions

Course Objectives

By the end of this course, participants will:

- Understand the importance of machinery safety and the risks associated with machinery use.

- Gain knowledge of hazard identification, risk assessment, and applicable safety standards.

- Learn how to implement effective machine guarding and safety controls.

- Master safe work practices, including Lockout/Tagout procedures.

- Be prepared to respond to and manage machinery-related emergencies.

Learning Outcomes

Upon successful completion of the course, participants will be able to:

- Identify potential mechanical hazards and assess associated risks.

- Apply safety standards and regulatory requirements to machinery use.

- Implement appropriate guarding solutions and safety measures.

- Conduct pre-operational inspections and ensure proper PPE use.

- Follow Lockout/Tagout procedures to control energy sources during maintenance.

- Investigate and respond effectively to machinery-related incidents.

Training Methodology

- Interactive Lectures:

- Use of multimedia presentations to explain concepts.

- Discussion of real-world examples and safety failures.

- Hands-on Training:

- Practical sessions with machinery for hazard identification and control application.

- Demonstrations of proper safety equipment and procedures.

- Group Activities:

- Role-playing exercises for emergency response scenarios.

- Team-based risk assessment tasks.

- Case Studies and Problem-Solving:

- Analysis of past incidents to identify root causes and preventive measures.

- Assessment and Feedback:

- Pre- and post-training quizzes to evaluate knowledge retention.

- Continuous feedback to address participant queries and challenges.

Location

Review

Write a ReviewThere are no reviews yet.