Popular

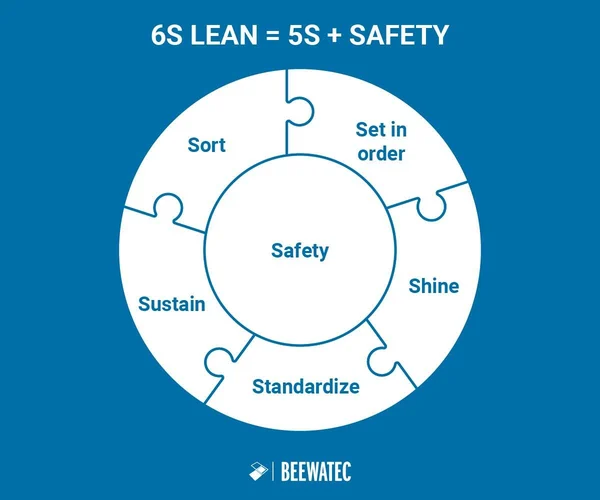

6 ‘s’ Implementation at Workplace

Description

Course Outline

Course Title: 6S Implementation at the Workplace

Duration: 2 days (16 hours)

Audience: Employees, supervisors, managers, and team leaders from any industry seeking to enhance workplace efficiency and organization through the 6S methodology.

Course Objectives

- Understand the principles and significance of the 6S methodology (Sort, Set in Order, Shine, Standardize, Sustain, and Safety).

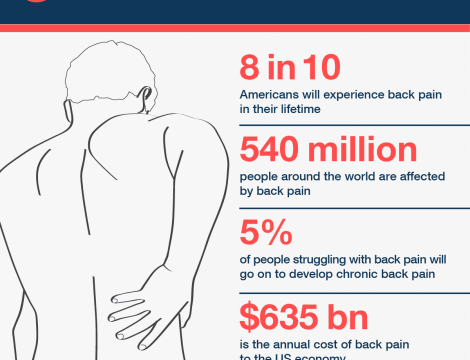

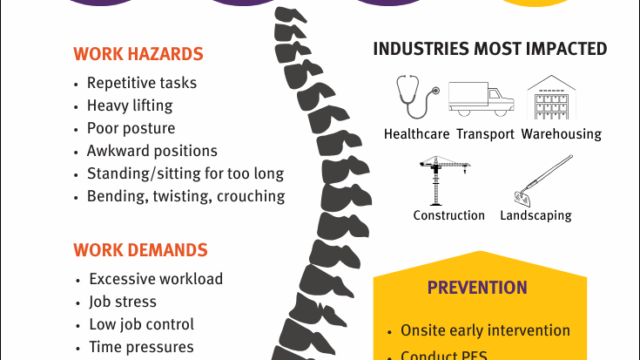

- Learn how to identify workplace inefficiencies and hazards.

- Acquire practical tools and techniques for implementing 6S principles in daily operations.

- Promote a culture of continuous improvement and employee engagement.

- Enhance workplace safety, efficiency, and productivity through effective 6S practices.

Learning Outcomes

By the end of this course, participants will be able to:

- Explain the core concepts and benefits of 6S.

- Conduct a workplace audit to identify areas for improvement using the 6S framework.

- Develop an actionable plan for implementing 6S in their workplace.

- Demonstrate practical skills in organizing, cleaning, and maintaining workplace areas.

- Monitor and sustain the 6S process while fostering a culture of safety and continuous improvement.

- Measure the impact of 6S implementation on safety, efficiency, and productivity.

Methodology

1. Interactive Lectures

- Use presentations, videos, and case studies to explain the 6S methodology and its real-world applications.

2. Hands-on Activities

- Practical exercises, including workplace simulations, sorting, and organizing activities.

3. Group Discussions

- Engage participants in discussions to share experiences and challenges related to workplace organization and safety.

4. Role-playing Scenarios

- Simulated problem-solving exercises to demonstrate the application of 6S in various scenarios.

5. Visual Tools and Templates

- Provide templates for workplace audits, checklists, and visual management tools to aid implementation.

6. Site Walkthrough (if applicable)

- Conduct a walkthrough of the actual workplace or a simulated space to identify opportunities for applying 6S principles.

7. Continuous Feedback and Coaching

- Offer personalized feedback during exercises and facilitate peer-to-peer coaching for skill development.

8. Implementation Planning

- Guide participants in creating a 6S action plan tailored to their specific workplace needs.

9. Follow-up Materials

- Provide post-training resources, including guides, checklists, and access to online forums for continuous learning and support.

Day-Wise Schedule

Day 1:

- Introduction to 6S Methodology

- Origins and importance of 6S

- Key principles and benefits

- Deep Dive into the 6S Steps

- Step 1: Sort – Identifying and eliminating unnecessary items

- Step 2: Set in Order – Organizing for efficiency

- Step 3: Shine – Cleaning and inspecting

- Practical Activities

- Sorting and organizing exercises in teams

- Group Discussion: Challenges in implementing 6S

Day 2:

- Remaining Steps of 6S

- Step 4: Standardize – Establishing procedures and visual controls

- Step 5: Sustain – Building habits and engaging employees

- Step 6: Safety – Embedding safety into each step

- Case Studies

- Success stories of 6S implementation in various industries

- Action Plan Development

- Conduct a workplace audit (real or simulated)

- Develop a step-by-step 6S implementation plan

- Evaluation and Feedback

- Presentation of action plans

- Group feedback and coaching

- Wrap-up

- Q&A session and course evaluation

- Distribution of resources and templates

Assessment

- Participation in discussions and activities

- Practical application during group exercises

- Quality of the implementation action plan

Location

Review

Write a ReviewThere are no reviews yet.