Popular

Energy Saving, Electrical Safety and Machinery Safety

Description

Course Outline

Module 1: Introduction to Energy Saving

- Importance of energy efficiency in industrial and commercial settings

- Basics of energy auditing

- Strategies for energy conservation in electrical systems

- Tools and technologies for energy monitoring and optimization

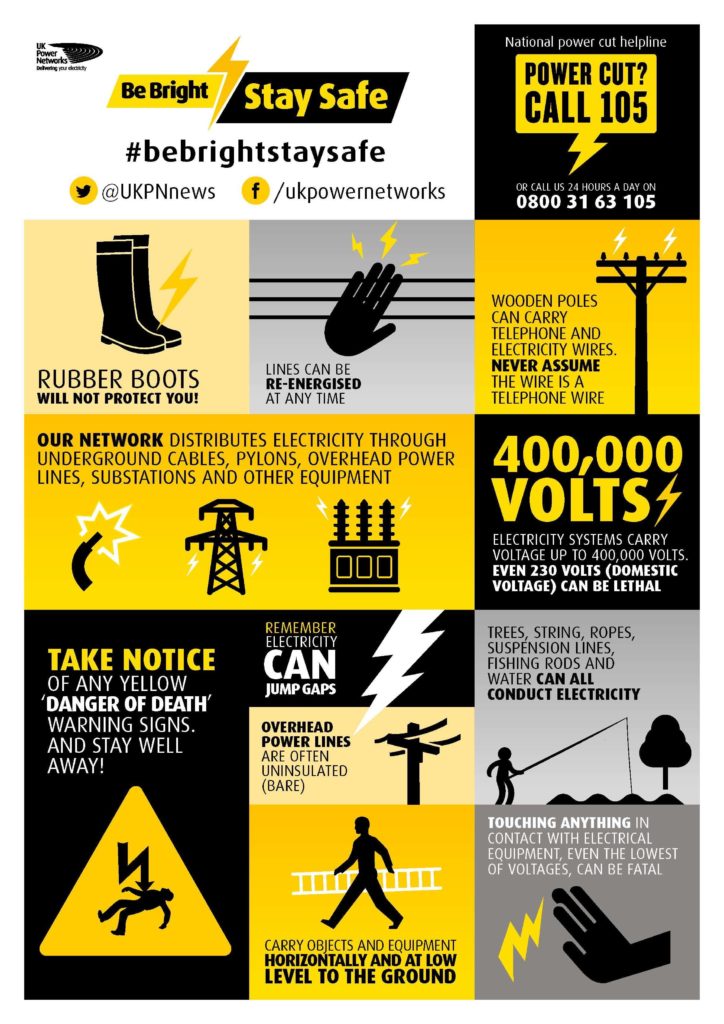

Module 2: Electrical Safety

- Understanding electrical hazards (shock, arc flash, fire risks)

- Workplace safety standards and regulations (e.g., OSHA, IEC, NFPA)

- Safe work practices for handling electrical equipment

- Lockout/Tagout (LOTO) procedures for electrical systems

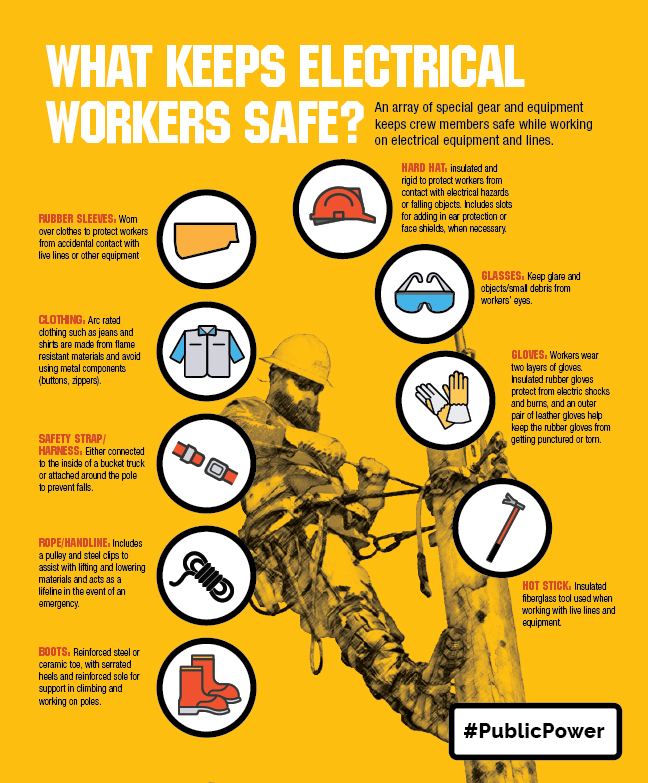

- Personal protective equipment (PPE) for electrical safety

Module 3: Machinery Safety

- Overview of machinery hazards and risk assessment

- Machine safeguarding techniques (guards, sensors, interlocks)

- Regulatory standards for machinery safety (e.g., ISO 13849, ANSI B11)

- Maintenance and inspection protocols for safe machinery operation

- Incident response and emergency planning for machinery-related accidents

Module 4: Integrated Safety and Efficiency Practices

- Aligning safety and energy-saving goals

- Case studies of successful implementations

- Best practices for ongoing safety and energy management

- Preparing an action plan for workplace application

Course Objectives

- Understand the principles of energy conservation, electrical safety, and machinery safety.

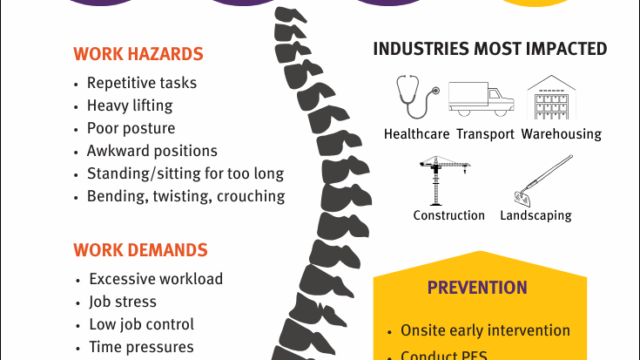

- Identify risks and hazards associated with electrical and machinery systems.

- Learn regulatory standards and compliance requirements for workplace safety.

- Apply energy-saving strategies to reduce operational costs and environmental impact.

- Implement safety protocols and risk management strategies for electrical and machinery systems.

Learning Outcomes

By the end of this course, participants will be able to:

- Conduct basic energy audits to identify inefficiencies in electrical systems.

- Recognize and mitigate electrical and machinery hazards in the workplace.

- Develop and enforce workplace policies for electrical and machinery safety.

- Implement energy-saving solutions without compromising safety standards.

- Monitor and maintain compliance with safety regulations and energy efficiency goals.

Methodology

The course will utilize a combination of:

- Lectures and Presentations: To cover theoretical aspects and regulatory standards.

- Interactive Workshops: Hands-on exercises to practice hazard identification, energy audits, and safety procedures.

- Case Studies: Analysis of real-world scenarios to reinforce practical application.

- Group Discussions: Collaborative problem-solving and sharing best practices.

- Quizzes and Assessments: To evaluate understanding and reinforce key concepts.

- Simulation and Demonstration: Use of simulation tools for energy efficiency and safety testing.

- Action Plan Development: Participants will create an actionable plan for implementing energy and safety improvements in their workplace.

Location

Review

Write a ReviewThere are no reviews yet.