Popular

Powered Industrial Truck Safety Driving

Description

Target Audience:

- New and experienced forklift operators

- Warehouse workers

- Construction site personnel

- Logistics and transportation employees

- Anyone required to operate powered industrial trucks as part of their job

1. Course Objectives

By the end of this training, participants will be able to:

- Understand OSHA regulations and workplace safety requirements for powered industrial trucks.

- Identify different types of powered industrial trucks and their specific applications.

- Recognize common hazards and implement safe operating practices.

- Perform pre-operation inspections and identify mechanical issues.

- Demonstrate safe driving, load handling, and maneuvering techniques.

- Understand pedestrian safety, blind spots, and workplace traffic rules.

- Respond appropriately to emergency situations and accidents.

2. Learning Outcomes

Upon successful completion, participants will be able to:

- Explain OSHA 29 CFR 1910.178 regulations governing powered industrial trucks.

- Conduct a proper pre-shift inspection and report safety concerns.

- Safely operate a powered industrial truck in various workplace settings.

- Apply correct loading, unloading, and stacking techniques to prevent tip-overs.

- Demonstrate awareness of pedestrian traffic and site-specific hazards.

- Perform emergency shutdown procedures and report accidents.

- Understand and implement safe refueling and battery charging practices.

3. Course Outline

Module 1: Introduction to Powered Industrial Trucks

- Definition and types of powered industrial trucks (PITs)

- Common workplace applications

- OSHA regulations and compliance requirements

Module 2: Hazard Recognition and Risk Management

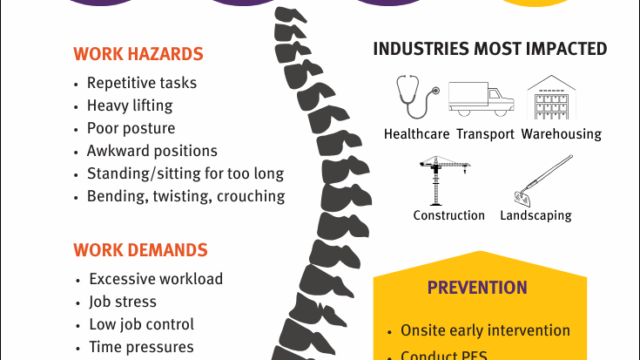

- Common PIT hazards (tip-overs, collisions, load instability)

- Pedestrian safety and site traffic management

- Environmental factors affecting safe operation

Module 3: Pre-Operational Inspection & Maintenance

- Daily safety checks (fluid levels, brakes, tires, forks, lights)

- Reporting and addressing mechanical issues

- Proper refueling and battery charging procedures

Module 4: Safe Operation Techniques

- Starting, stopping, and maneuvering techniques

- Load capacity and stability triangle principles

- Handling loads safely (lifting, stacking, and unloading)

- Operating on ramps, inclines, and uneven surfaces

Module 5: Workplace Traffic Rules & Pedestrian Safety

- Right-of-way rules and designated driving lanes

- Blind spots and communication signals

- Safe parking and shutdown procedures

Module 6: Emergency Procedures & Accident Response

- How to respond to PIT-related accidents

- Emergency stopping and shutdown

- Fire hazards and spill containment

Module 7: Hands-On Practical Training & Evaluation

- Conducting pre-use inspections

- Maneuvering exercises in a controlled environment

- Loading and unloading operations

- Final driving test and certification assessment

4. Training Methodology

- Classroom Instruction – Interactive lectures, videos, and case studies on PIT safety.

- Group Discussions – Sharing real-life workplace experiences and problem-solving.

- Hands-on Training – Practical demonstrations and supervised driving exercises.

- Simulations & Scenario-based Training – Emergency response drills and hazard recognition.

- Knowledge Assessment – Written test on PIT safety rules and best practices.

- Performance Evaluation – Practical skill assessment on a powered industrial truck.

5. Certification & Compliance

Upon successful completion, participants will receive:

- Powered Industrial Truck Safety Certificate (valid for three years or per company policy)

- OSHA-compliant training record documentation for employer compliance

- Recommendations for refresher training (as needed)

Location

Review

Write a ReviewThere are no reviews yet.